A simple enough circuit, the hardest part was adjusting the function generator to operate the coil correctly, as it was the first time I had used one. I also had a slight fault in my dwell time pattern, which I could not fully remove, even after replacing a few of the components

The next circuit I built used an ignition module to amplify a trigger signal to the coil. This circuit is alot like the last one I built, except the trigger is amplified by an ignition module, which means a much smaller signal is needed to ignite the spark. To wire this, I first had to find out the pin outs for the ignition module I was using, this particular one being from a Toyota 4a-fe engine. After some research on the always faithful Google, I found a pin out diagram, and also found the reason for the mysterious fifth pin (I already knew the use for the four others, just not which went where). The last pin was for a misfire detection function.

The four pins used on the ignition module consisted of Power Supply +12v, Earth, Trigger signal, and Output to Coil.

Other than figuring out the wiring of the ignition module, this circuit was quite simple to wire up, as it was very similar to the last, and the function generator was already calibrated.

The next circuit to build used a distributor to send a signal to the ignition module. The circuit was wired up alot like the last, but with a distributor in place of the function generator. Spinning the distributor rotor creates a signal much like that of the function generator, causing the spark to fire as each tooth of the rotor passes the pick up.

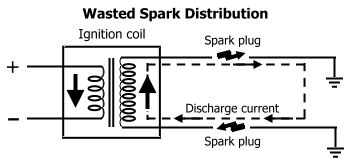

The next circuit to build used a distributor to send a signal to the ignition module. The circuit was wired up alot like the last, but with a distributor in place of the function generator. Spinning the distributor rotor creates a signal much like that of the function generator, causing the spark to fire as each tooth of the rotor passes the pick up. The third circuit I built was for a wasted spark ignition system. For this circuit, I used the function generator, and the same ignition module, but instead of the single plug coil, I used a wasted spark coil pack, with two leads and spark plugs. The wiring was much the same as the other circuits, except for the fact that there were two seperate spark plugs firing off the one coil. This is achieved by grounding one of the spark plugs through the other plug, and then back into the coil, to create a full circuit. The property of electricity that it naturally wants to return to its source, makes this possible.

Below is a simple diagram showing the internal functions of a wasted spark coil for a 6 cylinder vehicle.

On this coil, there is one 12v supply pin, but in others there may be one for each coil. It shows how two cylinders are triggered at the same time, and subsequently fire at the same time also. This is the reason for the name 'Wasted Spark', as one spark is always fired on the exhaust stroke.

The next circuit I built contained a Coil Over Plug setup, which contains a coil and built-in ignitor in one unit (see below), removing the need for a seperate ignitor. These units will run one coil for each cylinder, making them very efficient, and less likely to fail. A bad point is that the are difficult to test, as there is no access to the coil primary.